|

| |

| Extracting Water from the Board

|

|

| Evaporation is the key to home

remedies Picture a pot of water on the stove.

It will boil dry faster if you turn up the heat; if you use a shallow, big

diameter pan, rather than a tall, narrow one; and if you open the window

nearby. Same with your board - sort of:

Maximize the water's mobility! Put the wet board into

a warm space. Don't overdo it, though, lest you add heat problems to your

moisture problems. 110 degrees F would be about the warmest you can safely

go.

Maximize the surface area! Twirl a paper towel to a

point loosely, stuff into the vent fixture or the wound with a tooth pick,

making sure there is contact with the EPS foam, fan out at the top.

Maximize the dissipation! Point a fan at the wound or

vent fixture.

Which way around? Moist air is lighter than dry

air. For the most efficient drying, then, the wound (or vent fixture) should

be pointed up.

|

|

| Centrifugal Forces

The Spinner. I don't have one. The principle makes a

certain amount of sense, but the results seem wanting. The two boards I got

my hands on after they had been spun "dry" yielded better than 1/2# of water

each on the vacuum.

Its a charming idea in a Rube Goldbergian way - but

make sure to tie up the dog! (I'd like to think that my cats would be too

smart to chase after the rotating board :)

|

| Dehumidifying

Drying air by precipitating its moisture on a cool

surface

I am working on converting one of my storage rooms into

a dehumidifying space. The (limited) experiments I have conducted with

dehumidifyers indicate that the process is slow (due to the small

area of exchange) and best suited to remove the last small vestiges of water

from a board.

|

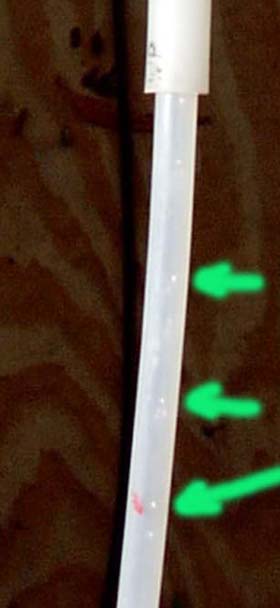

| Vacuum Drying

My preferred weapon

By creating a partial vacuum on the exterior of the

board, the steam pressure of the water inside becomes greater than the

exterior pressure. This causes the water to migrate to the surface, from

where it gets carried into a generous, baffled trap, ensuring that it will

not get into the pump. |

|

Careful adjustments of vacuum levels and ambient

temperature cause outflow of liquid water, as well as speed evaporation,

without crushing the board. Well, there was a bit of a learning curve here,

with exuberant heating leading to the collapse of an Airex-sheathed board (Airex

being quite thermoplastic). The owner was most gracious, though - thanks,

Peter Landsberg!!

What usually starts as an impressive flow, dwindles away

to only trace amounts as low moisture concentrations are achieved.

Given a recent intake of water, I can generally remove

enough moisture to read zero on the moisture meter. The longer the water has

been in the core, the less complete the evacuation.

While substantially faster than any of the above

methods, vacuum-drying can take months, if the water had a chance to migrate

into the EPS beads: a Northshore Maui board with over 6# of water in the

core for half a year, took 5 months to shed 5 1/2#.

Don't wait!!

|

|

|

return to

water, water everywhere |

|