|

|

Nelson-built Thommen, caught in the

shore break; deck buckled 15" aft of nose |

|

|

cut away anything that might interfere

with re-establishing the rocker; the individual layers still adhere

astoundingly well to each other |

|

|

clamp it back to shape (there is a 1/4"

sheet of plywood beneath, and some straight sticks across) |

|

|

inject marine Urethane foam, to hold the rocker (this is

one legitimate use of DuctTape in board repair - used here to force the

expanding foam down into the cracks and crevices - well, most of it...) |

|

|

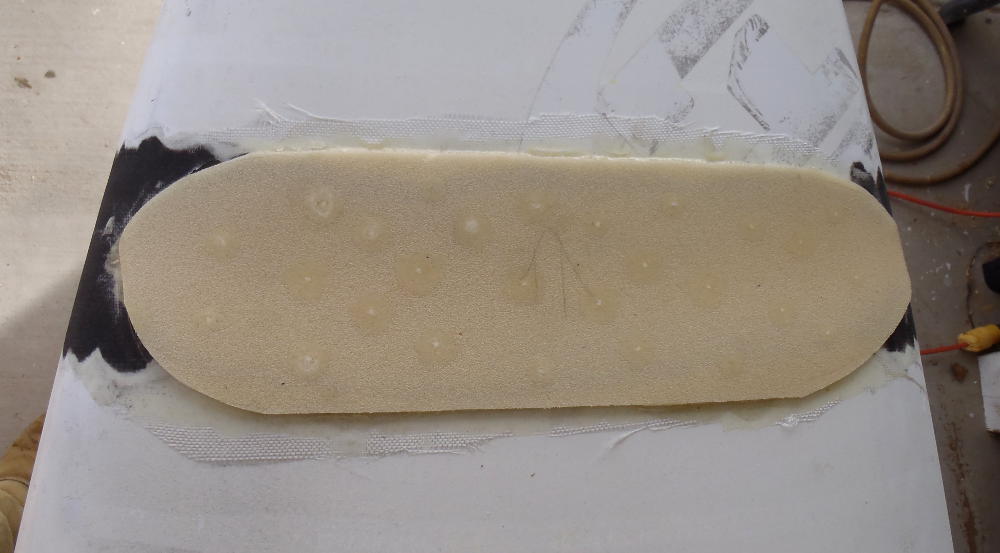

the fracture is bevel-ground; new piece of Corecell &

inner glass cut; vacuum tape in place, and bagging materials prepared |

|

|

the bonding surface is coated with a bit of filled Epoxy |

|

|

with the "rocker clamp" still in place, new inner glass

& Corecell are vacuum-bagged |

|

|

bagging supplies removed, revealing an odd-looking blob |

|

|

but when ground flush, it starts to make sense... new

reinforcements ready to go |

|

|

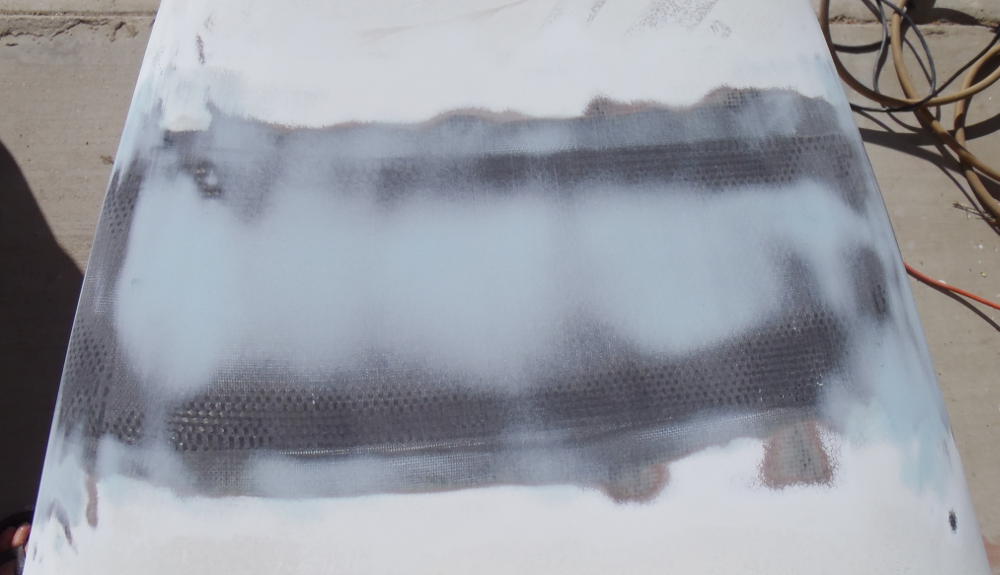

outer laminations done, replacing what I found there,

plus a layer of 4oz fiberglass cloth, to protect the Carbon during the

fairing process |

|

|

everything ground flush - not much fairing required,

just a bit of filling of texture |

|

|

Epoxy fairing compound slathered on |

|

|

and most of it sanded off again |

|

|

Epoxy primer applied |

|

|

painting day dawns warm and calm - perfect! |

|

|

nose painted and ready for new decal |

|

|

bottom rubbed out |

|

|

new decals and non-skid applied (DekDust in UV-resistant

Epoxy), then - after a proper curing interval - the whole thing given a good

bath weight gain 1 1/2oz (must be that Urethane foam I injected)

|

|

Return to assorted repairs |